Stainless Steel Screws for Durability & Performance in Construction Applications

- Stainless Steel Screws

In the construction industry, where durability is paramount, stainless steel screws stand out. Accounting for over 30% of all fasteners used in building projects, these screws are prized for their strength and exceptional resistance to corrosion. This article dives into the various types of stainless steel, particularly focusing on the A2 and A4 grades, which are essential for different environmental demands. Whether you’re a seasoned builder or just starting out, understanding the distinct benefits of these materials can significantly enhance the longevity and reliability of your projects.

Table of Contents

Types of Stainless Steel Used for Construction Applications

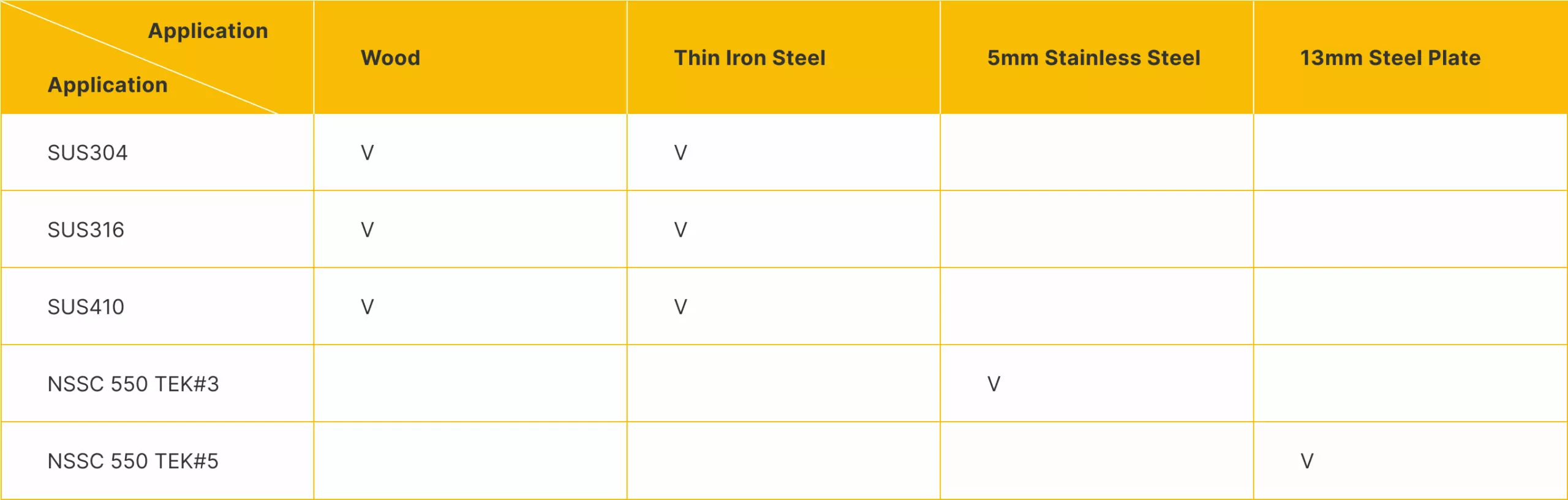

There are 5 common types of stainless steel that are used for construction and they are dependent upon the material that is being fastened, the following table will give you a guide to these applications:

We also have a comprehensive guide to Types of Stainless Steel Used by Screw Type which you can reference to learn more about the particular material types for your screw applications. If you are not sure which material is best for you then please ask us and we will be happy to advise you.

What are A2 and A4 Steels?

A2 and A4 are two common grades of stainless steel used in the manufacturing of screws and other fasteners. These grades are defined by their specific alloy composition, which determines their properties, such as corrosion resistance, strength, and durability.

A2 Stainless Steel (304 Grade)

- A2 stainless steel, also known as 304 grade, is the most widely used austenitic stainless steel.

- It contains a minimum of 18% chromium and 8% nickel, which provides good corrosion resistance in various environments.

- A2 stainless steel is resistant to oxidation, rust, and moderate chemicals.

- It is commonly used in food processing equipment, kitchen utensils, and architectural applications.

- A2 stainless steel screws are suitable for indoor and less corrosive environments.

A4 Stainless Steel (316 Grade)

- A4 stainless steel, also known as 316 grade, is an austenitic stainless steel with enhanced corrosion resistance properties.

- In addition to chromium and nickel, A4 stainless steel contains 2-3% molybdenum, which further improves its resistance to corrosion, particularly in chloride-containing environments.

- A4 stainless steel is more resistant to salt water, industrial chemicals, and acids compared to A2 stainless steel.

- It is commonly used in marine applications, chemical processing equipment, and environments with high humidity or exposure to corrosive substances.

- A4 stainless steel screws are ideal for outdoor applications, coastal areas, and projects requiring superior corrosion resistance.

Both A2 and A4 stainless steels offer excellent corrosion resistance, durability, and strength. However, A4 stainless steel provides an enhanced level of protection against corrosion, making it suitable for more demanding environments. The choice between A2 and A4 stainless steel screws depends on the specific requirements of the application, such as the level of corrosion resistance needed, environmental factors, and project specifications.

For more detailed information on stainless steel grades please refer to this guide to ASTM standards for stainless steels published by the British Steel Association.

Common Applications of Stainless Steel Screws in Construction

Stainless steel screws find extensive use in a wide range of construction applications, each with its unique requirements and challenges. Understanding these applications is crucial for selecting the most appropriate stainless steel screws that can withstand the specific demands of the project.

Stainless Steel Screws for Roofing Cladding

Stainless steel roofing screws (304) are extensively used in aluminum roofing applications to provide a secure and long-lasting hold for roofing materials. In coastal regions and areas with high humidity, the corrosion resistance of stainless steel screws is key. By opting for 304 stainless steel screws, builders can ensure that the fasteners remain intact and functional, preventing water infiltration and maintaining the overall weatherproofing of the building. It is important to note that for other non aluminum roofing materials, galvanized screws are commonly used as stainless steel screws would be more expensive and not needed for those applications.

Fastening Wood & Composite Decking with Stainless Steel Screws

Decking applications, whether using traditional wood or modern composite materials, greatly benefit from the use of stainless steel screws. These screws offer superior resistance to rust and corrosion, which is crucial in outdoor environments exposed to moisture and varying weather conditions. Stainless steel screws prevent unsightly rust stains on the decking surface, maintaining the aesthetic appeal of the deck. The durability of stainless steel ensures that the screws can withstand constant exposure to the elements, foot traffic, and the natural expansion and contraction of the decking materials over time.

Stainless Steel Screws for HVAC & Electrical Systems

Stainless steel screws are commonly used in the installation and assembly of HVAC (Heating, Ventilation, and Air Conditioning) ductwork and electrical panels. These applications demand reliable and corrosion-resistant fasteners to ensure the proper functioning and safety of the systems. HVAC ducts are often exposed to moisture and condensation, which can lead to corrosion of regular steel screws. The most common screw types used for HVAC are 410 stainless steel self tapping TEK screws.

Electrical panels and junction boxes require screws that can withstand potential exposure to moisture and prevent electrical hazards. By utilizing stainless steel TEK screws in these applications, contractors can ensure the longevity and reliability of the HVAC and electrical systems, minimizing the risk of failures and potential safety concerns whilst also providing a long lasting finish that provides visual appeal in the long term.

Factors to Consider When Choosing Stainless Steel Screws for Construction

When selecting stainless steel screws for construction projects, several key factors must be considered to ensure optimal performance and longevity.

Environmental Conditions

Assessing the environmental conditions to which the screws will be exposed is crucial. Factors such as moisture, chemicals, and temperature fluctuations can impact the performance of the screws over time. In environments with high humidity or exposure to corrosive substances, it is essential to select the appropriate stainless steel alloy, such as 304 or 316, which offer varying levels of corrosion resistance. By carefully evaluating the environmental factors, engineers and builders can choose the most suitable stainless steel screws that will withstand the specific challenges of the project site.

Load-Bearing Requirements

The load-bearing requirements of the application must be carefully considered when selecting stainless steel screws. Different construction elements, such as structural components, roofing, and decking, have varying load capacities and stress factors. It is essential to determine the necessary strength and durability of the screws based on the specific application to ensure they can withstand the anticipated loads and stresses. Consulting with structural engineers and referring to building codes and regulations can help in selecting the appropriate screw size, grade, and type that will meet the load-bearing requirements of the construction project.

Aesthetics

In addition to their functional properties, stainless steel screws can also contribute to the overall aesthetics of the construction project. In exposed areas, such as architectural features or decorative elements, the visual impact of the screws should be considered. Stainless steel screws are available in various finishes, including polished, brushed, or coated, which can be selected to match the desired design intent. By carefully choosing the right finish, builders can ensure that the screws complement the overall appearance of the construction while still providing the necessary structural integrity.

Why Choose Cheng Hao for Your Stainless Steel Screw Needs?

Cheng Hao’s Expertise in Custom Screw Manufacturing With 20 years of experience as a global custom screw manufacturer and supplier, Cheng Hao brings a wealth of expertise to the construction industry. Our company’s strong supply chain control and logistics management ensure a reliable and efficient delivery of high-quality stainless steel screws to our global customers. Cheng Hao serves international distributors, machine tool and metal product manufacturers, as well as businesses in the electronics, medical, construction, furniture, automobile, and bicycle industries with the supply of bulk screws.

What sets Cheng Hao apart is its commitment to quality, custom solutions, and certifications. The company offers custom quality inspection to ensure that each batch of screws meets the highest standards of precision and consistency. Cheng Hao also provides custom packaging solutions to meet the specific needs of its customers, ensuring safe and efficient transportation and storage of the screws.

In addition to standard stainless steel screws, Cheng Hao specializes in custom screw designs and specialist fasteners. The company’s engineering team works closely with customers to develop tailored solutions that address the unique requirements of their construction projects. This collaborative approach enables Cheng Hao to deliver stainless steel screws that are optimized for specific applications, ensuring optimal performance and reliability.

To find out more about our stainless steel screws or other screw and fastener offerings, please contact us with your specific requirements for a rapid quote.