Lathe tool holder screws for Turning Centers and Milling Cutters represent a remarkable advancement in the fastening hardware used in machining applications. Made from Hardness grade 16.4, NSSC550 stainless steel, these screws surpass the strength of traditional materials like SCM435 alloy steel. The outcome is a significant enhancement in the operational efficiency and service life of the turning and milling cutter shanks.

The key benefits of these lathe tool holder screws lie in their superior corrosion resistance and high hardness and strength. The screws don’t get stuck due to corrosion, reducing the need for anti-jam glue and time spent on gluing operations. Additionally, the Torx (six-lobe) hole (needle type) in these screws is designed to resist damage or deformation. It minimizes the chance of breaking the screw head, avoiding the necessity to replace the entire cutter shank.

These lathe tool holder screws also offer the ability to create an exceptionally tight lock, ensuring that vibrations during operation don’t lead to missing notches and increased tool blade wear. This feature not only saves significant operational time and the cost of replacing tool blades but also substantially improves the accuracy of the work piece surface.

In our production setup, we place a high emphasis on ensuring the supreme quality of every lathe tool holder screw we create. Every order is subjected to rigorous quality checks and comprehensive inspections, reaffirming the unwavering quality we stand by across our entire product line.

Our robust inspection practices ensure that every batch is scrutinized in detail to align with our rigorous quality standards. To exemplify our commitment to superior quality, an inspection certificate accompanies each shipment. Should you have any specific requests regarding the quality assurance process, do let us know, and we’ll strive to meet your individual needs.

We can offer customers a wide range of custom packaging options for your orders to suit your particular distribution needs. Please let us know and we will do our best to oblige you with the best packaging option for you.

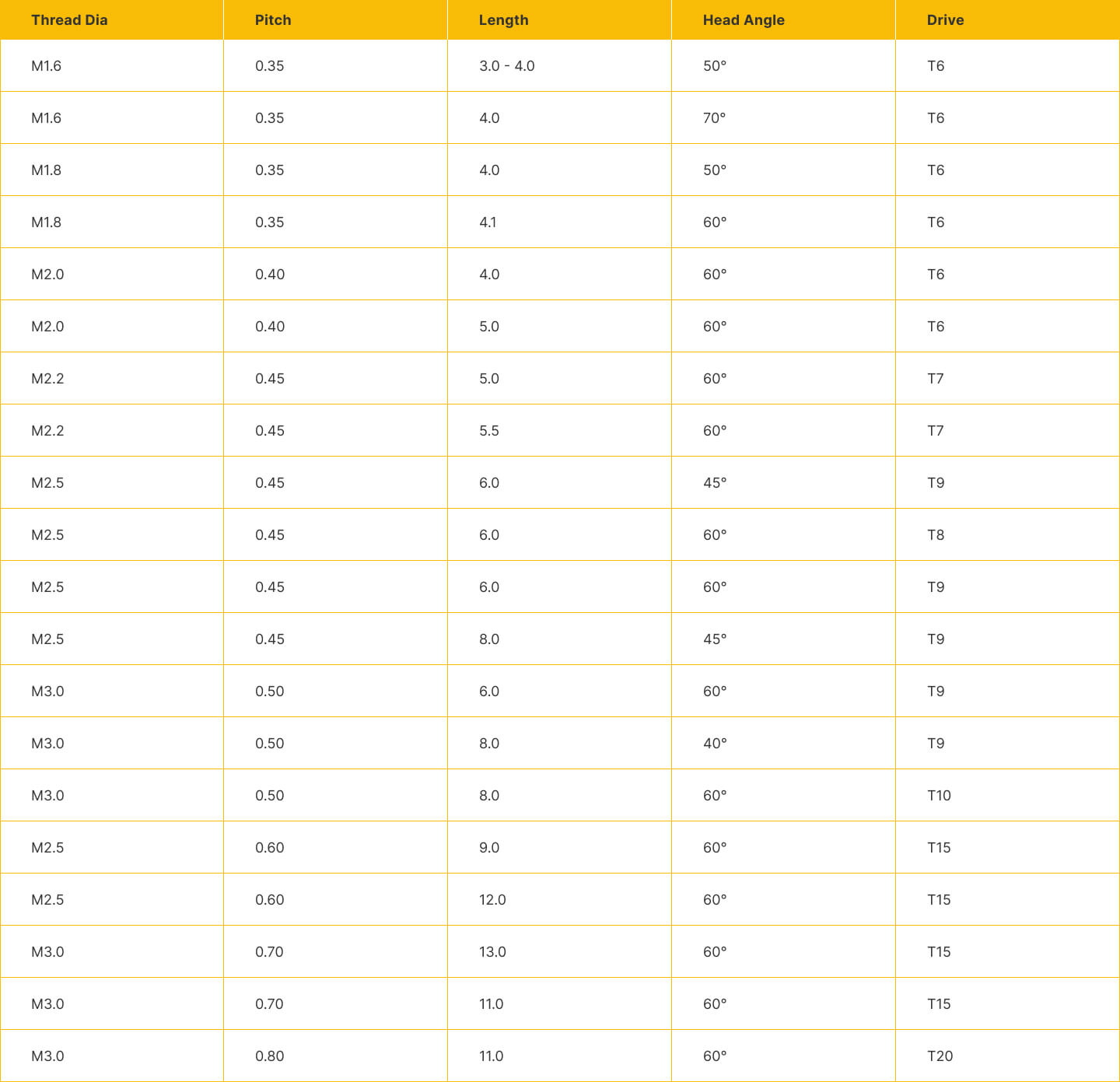

Please view our commonly ordered screw types below or let us know your special requirements for custom screws.

These are some of the most frequently asked questions by our customers. We hope they are helpful to you. If you cannot find the answer you need, please contact us using the inquiry button below.

We are a professional precision screw manufacturer operating directly. We also represent various fastener products from Taiwan, forming a comprehensive supply chain to ensure quality. We welcome your inquiries.

Our product range includes screws, bolts, nuts, precision small screws, SEMS screws, washers, rivets, CNC precision machining, metal stamped parts, and a variety of custom fasteners.

The delivery time largely depends on the quantity of the order. We have some standard specification products in stock, while custom products typically take between 30 to 75 days for delivery.

Yes, we can provide samples upon request. However, due to the vast array of screw specifications, we might not have the exact specifications you need in stock. In that case, we will send you products with similar specifications for your reference.

If you require a customized product, we will produce a small batch of samples for your approval after you place your order. Once you confirm the samples, we will proceed with mass production.

Customization is our forte. You can provide us with diagrams, design drawings, or a list of requirements, and our expert team will provide a quote based on your specifications.

Please provide the specifications and quantity of the screws you need. Specifications should include material, surface treatment, head type, driver type, thread type, point type, and dimensions (Metric, Imperial, US).

The MOQ varies depending on the material. As a professional screw manufacturer, our MOQ is 50,000 pieces for stainless steel and 100,000 pieces for carbon steel. This requirement, which may seem high to some customers, is designed to ensure product quality, cost-effectiveness, production efficiency, and shipping efficiency, and to pass on price benefits to customers. For special-purpose screws or orders with a high total quantity, we also support a lower MOQ, making cooperation very convenient.

Carbon steel screws will rust when exposed to moisture unless they are coated with an anti-rust coating or made of stainless steel. However, if the anti-rust coating is worn or chipped due to external factors, thereby reducing its anti-rust strength, rust may occur under the coating. Stainless steel screws are the most resistant to rust and corrosion. Although they are more expensive, their rust resistance is not easily reduced because the entire structure of the screw is stainless steel.

Our products are certified by ISO 9001, which is an international standard for quality management systems. This certification ensures that we adhere to best practices for producing high-quality products that meet our customers’ expectations and requirements.

Some of our products also have CE certification, which is a mark that indicates conformity with health, safety, and environmental protection standards for products sold within the European Economic Area. Please contact us for CE-certified products.

| Service | Cookies | Description |

|---|---|---|

| Google Analytics | _gat_gtag, _ga, _gid | Used to distinguish users and sessions for web statistics purposes. |

| Service | Cookies | Description | |

|---|---|---|---|

|

|

Google Analytics | _gat_gtag, _ga, _gid | Used to distinguish users and sessions for web statistics purposes. |