Deck Screws: The Key to a Secure and Durable Deck

When it comes to building a deck, choosing the right fasteners is crucial to ensure long-lasting durability and safety. Deck screws, specifically designed for outdoor projects, provide a secure connection between decking boards and joists, with features tailored to withstand harsh environmental conditions. This guide explores the essential characteristics of deck screws, their advantages over traditional wood screws, and why they are the go-to choice for professional construction companies. Whether you’re working with wood or composite materials, understanding the nuances of deck screws can make all the difference in delivering a high-quality result.

Table of Contents

What Are Deck Screws?

Deck screws are specially engineered fasteners intended for use in outdoor decking installations. Unlike standard wood screws, deck screws are designed to resist corrosion, provide enhanced grip, and reduce the risk of wood splitting. They play a critical role in maintaining the structural integrity of a deck over time, especially when exposed to varying weather conditions.

Functions and Key Features of Deck Screws

- Corrosion Resistance

One of the most critical features of deck screws is their resistance to corrosion. Made from materials like stainless steel or coated with zinc, deck screws are built to withstand moisture, air exposure, and even saltwater environments. Coated screws can endure up to 2000 hours of salt spray testing, ensuring their longevity in coastal or humid climates. This corrosion resistance is crucial for outdoor applications where screws are constantly exposed to the elements. - Self-Drilling Tips

Many deck screws feature self-drilling tips, allowing for faster and easier installation. This eliminates the need for pre-drilling, saving both time and effort while reducing the likelihood of splitting the wood. Self-drilling tips ensure a cleaner, more professional finish, especially when dealing with hardwood or treated lumber. - Thread Design

Deck screws typically have coarse, deep threads that provide superior grip, holding decking boards securely in place. This design prevents the screws from loosening over time due to the natural expansion and contraction of the wood. The enhanced grip also minimizes the risk of boards warping or shifting, contributing to the deck’s overall stability. - Bugle Head Design

The bugle-shaped head of deck screws prevents over-driving, ensuring the screw sits flush with the decking surface without damaging the wood fibers. This design feature distributes pressure evenly, reducing the likelihood of surface cracking or denting while providing a neat and clean finish. - Compatibility with Treated Lumber

Modern decks often use pressure-treated wood, which contains chemicals to enhance durability. Deck screws are typically ACQ-compatible, meaning they can be safely used with treated lumber without causing corrosion. This compatibility makes deck screws the preferred choice for projects requiring high durability and weather resistance.

1. Comparison of Deck Screws vs. Wood Screws

This table is a quick reference to clearly show the differences between deck screws and wood screws to help you to identify them more easily.

A study from the Florida Department of Environmental Protection found that non-corrosion-resistant screws in coastal environments showed visible signs of rust within 6 months, leading to premature failure in over 30% of installations within 2 years.

2. Recommended Deck Screw Lengths Based on Decking Board Thickness

Please use this table to determine the correct length of deck screw based on the thickness of the board you are screwing into.

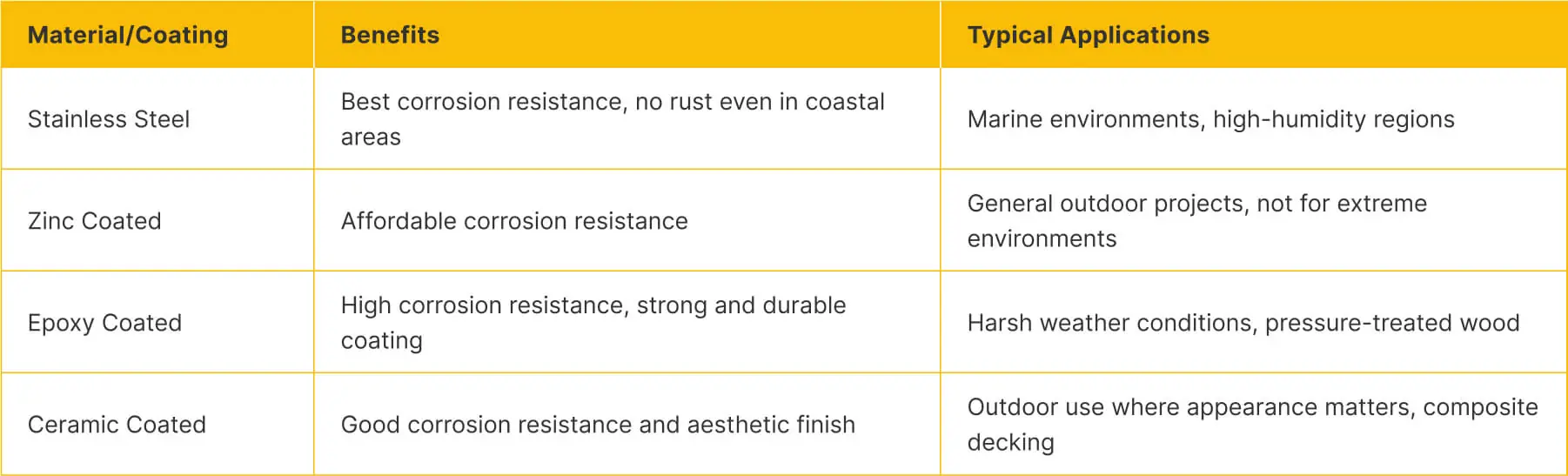

3. Common Coatings and Materials for Deck Screws

The following reference table provides a general guide to the materials, and their applications and benefits when selecting the correct deck screw material for your project.

Composite Decking Screws: A Specialized Solution

In addition to traditional wood decks, many builders today are opting for composite decking materials, which are made from a blend of wood fibers and plastic. Composite decking screws are specifically designed to accommodate the unique characteristics of these materials.

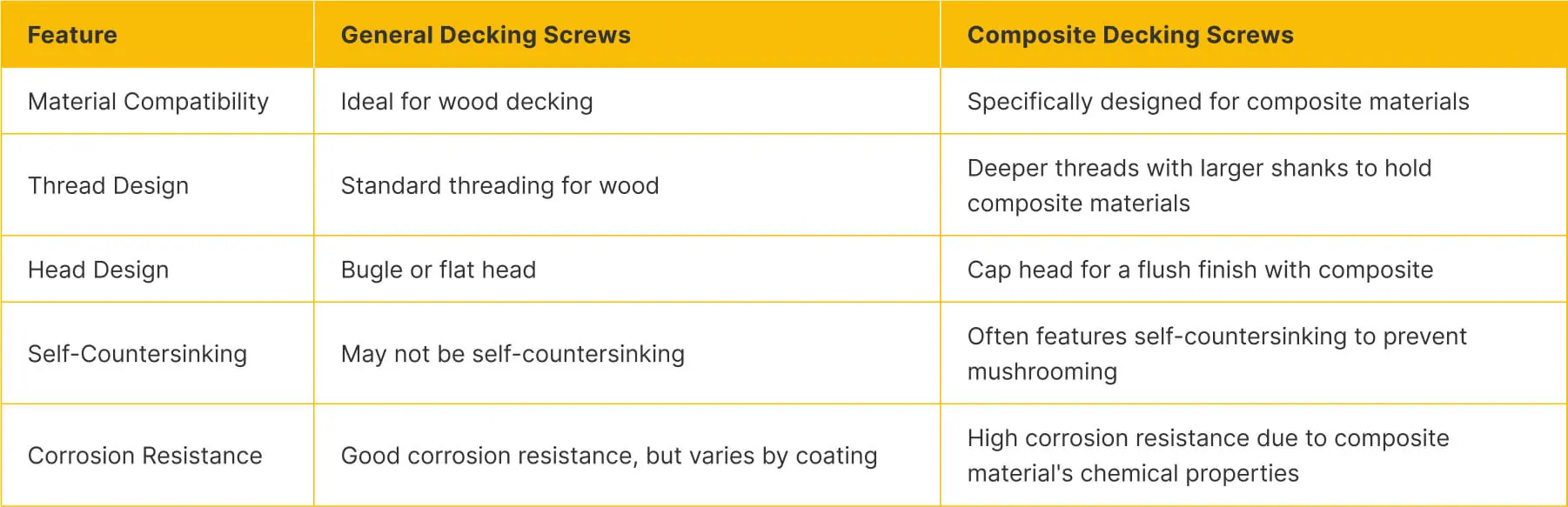

1. Comparison of General Decking Screws vs. Composite Decking Screws

The following table will help you to easily differentiate between composite and general decking screws so that you can accurately select the correct type for your project.

According to the Journal of Light Construction’s study on fastener corrosion 20-30% of deck failures are due to fastener issues, so choosing the appropriate fastener for your installation is vital.

2. Key Features of Composite Decking Screws

- Material and Coating

Like wood deck screws, composite decking screws are made from corrosion-resistant materials like stainless steel or coated steel. However, these screws often come in a variety of colors to match the decking material, providing a more aesthetically pleasing finish. - Thread Design

Composite decking screws typically feature tri-lobe threads and inverted upper threads, which minimize damage to the composite material. This ensures that the screws can be driven in smoothly without causing mushrooming or surface blemishes. - Head Design

The cap head design of composite decking screws allows them to sit flush with the surface, providing a smooth, clean-looking installation. Many of these screws also feature self-countersinking heads, which eliminate the need for pre-drilling and make installation faster and more efficient. - Ease of Installation

Composite decking screws are engineered for easy installation. Self-drilling tips allow them to penetrate composite materials without the risk of cracking or splitting, and some even come in collated strips for use with auto-feed systems.

Why Choose Cheng Hao Deck Screws?

As a leading manufacturer and supplier of screws, Cheng Hao offers a wide range of deck screws designed for both wood and composite materials. Based in Taiwan, Cheng Hao is known for its commitment to quality, producing screws that meet international standards. The company’s deck screws are manufactured using high-grade materials and advanced coatings, ensuring superior corrosion resistance and long-term durability.

With a focus on precision and performance, Cheng Hao’s screws are ideal for large-scale decking projects, providing construction companies with the reliability they need to deliver outstanding results.

Cheng Hao’s ability to produce custom screws tailored to specific project requirements sets it apart from other suppliers. Whether you need specialized screws for unique materials or large quantities for extensive projects, Cheng Hao’s flexibility and expertise ensure that you get the right product for the job.