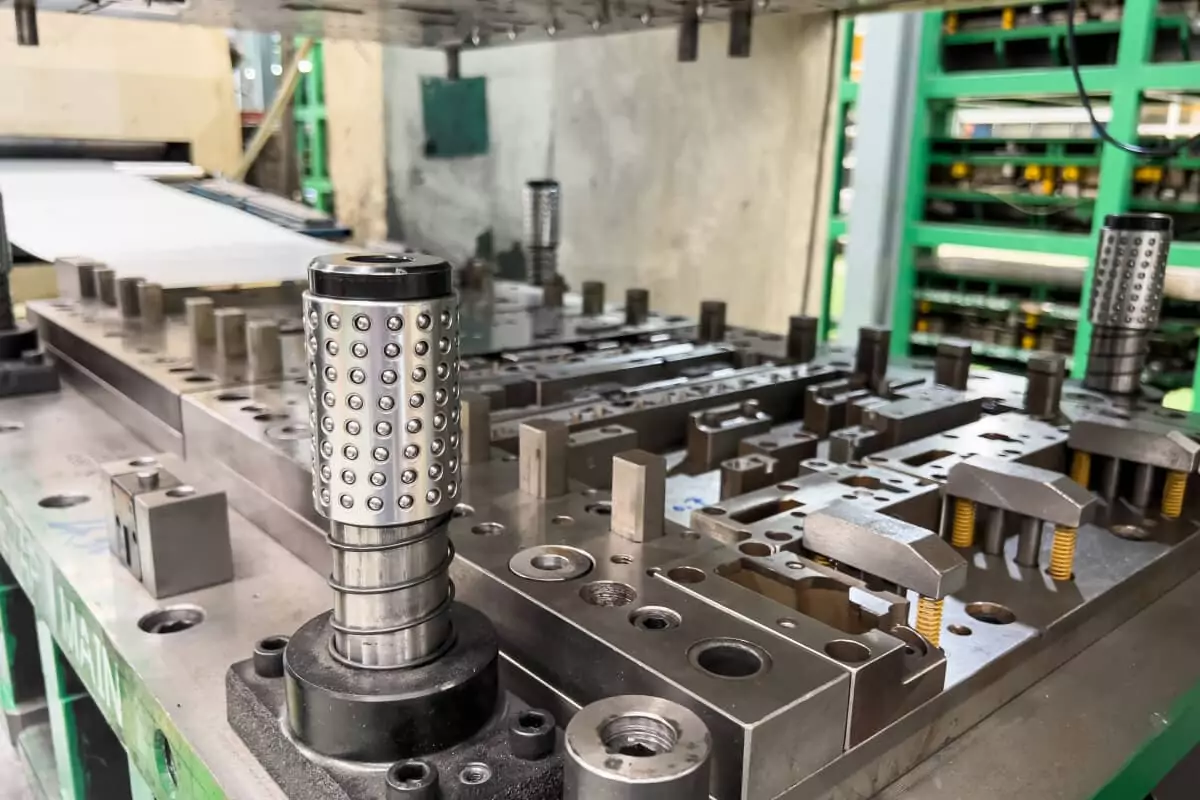

We specialize in the manufacturing of high-quality custom metal stamped parts. This process involves applying pressure to metal sheets or wires in a die, transforming them into various shapes (including complex ones) and sizes to create components. Metal stamping is a highly efficient and precise method of manufacturing, and these components play a crucial role in numerous industries. They’re integral to the assembly of various devices and structures, where they serve as panels, casings, interfaces, and internal structures.

With Cheng Hao, you can be assured of high-quality, custom, metal stamped parts, designed and manufactured to meet your exact specifications. Our service includes high speed and miniature stamping for smaller electronic contacts and components such as: connectors, sensors, relays, automotive wiring harnesses, medical device parts, communication equipment’s electronic components, smart home accessories

Our metal stamped components are used in a variety of applications in the automotive industry, from vehicle body parts to intricate engine components.

Our precision stamping can create connectors, terminals, and other components that are critical to electronic devices.

Our precision components cater to the demanding standards of the medical industry, where quality and reliability are paramount.

In machinery, our stamped components play a key role in creating efficient and reliable mechanical systems.

We manufacture components that are vital in both the structural and aesthetic elements of the construction and decor sectors.

We supply components for various household appliances where durability and precision are required.

Please check our screw specifications page to see the wide range of options we can supply or contact us now with your detailed requirements.

Choose based on the product’s intended use, application method, and customer requirements.

Commonly used types include SUS302, SUS304, SUS316, SUS410. A special type called NSSC550 is exclusive to Cheng Hao, which has high hardness, high corrosion resistance, and high acid resistance. Its rust prevention is 15 times better than existing materials for screws.

Low carbon steel, medium carbon steel, high carbon steel.

Refers to steel materials that, besides containing carbon, also have other alloying elements such as silicon, manganese, chromium, nickel, vanadium, molybdenum, etc.

Common material codes include 2011, 2024, 6061, 6082, 7075.

Brass (Yellow brass), Bronze.

Choose based on the product’s intended use, application method, and customer requirements.

We boast decades of experience as a metal stamped parts supplier to some of the largest manufacturers in the industry. We attentively monitor every stage of the process, from supply chain management, manufacturing, right through to logistics and shipping to ensure your order reaches you in a timely manner.

In terms of packaging options, we offer both standard and custom solutions for our bulk purchase customers. We invite you to share your specific requirements with us so that we can design an optimal packaging solution that perfectly meets your production needs. With Cheng Hao, rest assured that your metal stamping needs will be addressed with the utmost professionalism and dedication.

These are some of the most frequently asked questions by our customers. We hope they are helpful to you. If you cannot find the answer you need, please contact us using the inquiry button below.

We are a professional precision screw manufacturer operating directly. We also represent various fastener products from Taiwan, forming a comprehensive supply chain to ensure quality. We welcome your inquiries.

Our product range includes screws, bolts, nuts, precision small screws, SEMS screws, washers, rivets, CNC precision machining, metal stamped parts, and a variety of custom fasteners.

The delivery time largely depends on the quantity of the order. We have some standard specification products in stock, while custom products typically take between 30 to 75 days for delivery.

Yes, we can provide samples upon request. However, due to the vast array of screw specifications, we might not have the exact specifications you need in stock. In that case, we will send you products with similar specifications for your reference.

If you require a customized product, we will produce a small batch of samples for your approval after you place your order. Once you confirm the samples, we will proceed with mass production.

Customization is our forte. You can provide us with diagrams, design drawings, or a list of requirements, and our expert team will provide a quote based on your specifications.

Please provide the specifications and quantity of the screws you need. Specifications should include material, surface treatment, head type, driver type, thread type, point type, and dimensions (Metric, Imperial, US).

The MOQ varies depending on the material. As a professional screw manufacturer, our MOQ is 50,000 pieces for stainless steel and 100,000 pieces for carbon steel. This requirement, which may seem high to some customers, is designed to ensure product quality, cost-effectiveness, production efficiency, and shipping efficiency, and to pass on price benefits to customers. For special-purpose screws or orders with a high total quantity, we also support a lower MOQ, making cooperation very convenient.

Carbon steel screws will rust when exposed to moisture unless they are coated with an anti-rust coating or made of stainless steel. However, if the anti-rust coating is worn or chipped due to external factors, thereby reducing its anti-rust strength, rust may occur under the coating. Stainless steel screws are the most resistant to rust and corrosion. Although they are more expensive, their rust resistance is not easily reduced because the entire structure of the screw is stainless steel.

Our products are certified by ISO 9001, which is an international standard for quality management systems. This certification ensures that we adhere to best practices for producing high-quality products that meet our customers’ expectations and requirements.

Some of our products also have CE certification, which is a mark that indicates conformity with health, safety, and environmental protection standards for products sold within the European Economic Area. Please contact us for CE-certified products.

| Service | Cookies | Description |

|---|---|---|

| Google Analytics | _gat_gtag, _ga, _gid | Used to distinguish users and sessions for web statistics purposes. |

| Service | Cookies | Description | |

|---|---|---|---|

| Google Analytics | _gat_gtag, _ga, _gid | Used to distinguish users and sessions for web statistics purposes. |