Machine Screws 101 – Understanding & Selecting the Fastener for Your Needs

- Machine Screws

Machine screws play a vital role in modern manufacturing and with the rapid expansion of the automotive and construction sectors this market is expected to grow steadily for the rest of the decade with a CAGR of 4.3%.

Table of Contents

From the delicate assembly of medical devices to the construction of heavy machinery, these small fasteners hold countless components together, ensuring functionality and safety. However, for engineers and procurement specialists in the appliance, medical, automotive, and machinery industries, selecting the right machine screw for a specific application can be a complex task. With a wide variety of materials, sizes, head styles, and drive types to consider, choosing the wrong screw can lead to costly mistakes – malfunctions, safety hazards, and production delays.

In this comprehensive guide, we will equip you with the knowledge needed to make informed decisions about machine screws. We’ll examine the essential characteristics of these fasteners, and explore the different options available.

How Are Machine Screws Different from Other Screws?

Machine screws stand out from regular screws in several key ways. Firstly, they’re manufactured to tighter tolerances, boasting finer threads and a more consistent overall build. Unlike regular screws with partially threaded shanks, machine screws are threaded nearly their entire length, offering a larger gripping area for a stronger hold. Machine screws also have flat or blunt tips, designed to fit snugly into pre-drilled and tapped holes. These features make them ideal for applications demanding high levels of security and precise fastening.

The Most Common Types of Machine Screws

Here at Cheng Hao, we offer a wide variety of machine screws to suit your specific needs:

- Lathe Tool Holder Machine Screws: These are designed for secure attachment of lathe tool holders, ensuring precise tool positioning during metalworking operations.

- Standard Machine Screws: Our most versatile option, standard machine screws come in a wide range of sizes and head styles, perfect for general-purpose fastening in machinery, construction, and various other applications.

- Custom Machine Screws: Need a screw that’s not quite standard? Cheng Hao offers custom machine screw production tailored to your exact specifications, ensuring a perfect fit for unique projects.

- T-Head Machine Screws: Featuring a T-shaped head, these screws provide increased grip for hand tightening and are ideal for applications requiring frequent adjustment or disassembly.

- Micro Machine Screws: For intricate electronic devices and miniature projects, our micro machine screws offer exceptional precision in a compact size.

- Socket Set Machine Screws: These screws have a recessed internal hex socket for installation with a hex key or Allen wrench, providing a clean and low-profile aesthetic.

- SEMS Machine Screws: An all-in-one solution, SEMS screws combine a standard screw with a pre-assembled washer that helps prevent loosening due to vibration. Pre-assembled screws and washers save time during assembly processes. There’s no need to handle multiple components, making the process faster and more efficient especially in production line scenarios.

Anatomy of a Machine Screw

Let’s take a closer look at the different parts that make up a machine screw. These are the some of the specifications that you will need to consider when asking for a quotation for this type of product:

Common Machine Screw Head Styles

- Flat Head: sits flush with the surface for a low-profile design, often used in applications with limited space (e.g., appliances).

- Button Head: rounded head offering a clean look, suitable for general-purpose applications.

- Socket Head: has a hexagonal recess requiring an Allen wrench for tightening, ideal for applications requiring high torque or limited clearance for a tool (e.g., machinery).

- Pan Head: has a rounded head with a cylindrical sidewall, offering a good grip for manual tightening.

For a complete list of the head styles we can manufacture, please refer to the specifications page section on head types

Machine Screw Thread Types Explained

Machine screws come in two primary thread types: coarse and fine. Coarse threads offer a faster assembly process due to their wider spacing. They’re well-suited for general-purpose fastening where high vibration resistance isn’t a major concern.

Fine threads, on the other hand, boast a tighter pitch, providing a stronger grip and better resistance to vibration. These are ideal for applications requiring exceptional precision and stability.

You will have to specify the screw body (shank) length, and tip type in order to provide a complete description of your needs. If you need more information on this please check our page on screw specifications or contact us directly for more assistance.

Material Selection for Machine Screws

Choosing the right material for your machine screw is just as important as selecting the appropriate size and head style. Different materials offer varying properties, making them suitable for specific environments and applications. Here’s a breakdown of some common materials used in machine screws across the appliance, medical, automotive, and machinery industries:

Steel: The most widely used material due to its affordability, strength, and versatility.

- Low-carbon steel: Offers good machinability and formability, ideal for general-purpose applications in appliances and some automotive parts.

- Medium-carbon steel: Provides increased strength for applications requiring more load-bearing capacity, common in machinery.

- High-carbon steel: Offers the highest strength among common steels, suitable for high-stress applications in automotive engines or heavy machinery.

Stainless Steel: Known for its excellent corrosion resistance, making it ideal for applications exposed to moisture or harsh environments, such as medical devices and appliances in kitchens or bathrooms.

Brass: Offers good corrosion resistance, machinability, and a decorative appearance, often used in applications requiring a non-sparking material or a touch of aesthetic appeal (e.g., some appliance components).

Aluminum: Lightweight and corrosion-resistant, suitable for applications where weight reduction is crucial, such as some automotive parts or aerospace applications (although not as common in the other target industries).

We prioritize using high-quality materials and adhere to strict quality control measures throughout the manufacturing process. We offer a wide selection of materials to meet the diverse needs of your projects across various industries. The optimal material selection depends on factors like strength requirements, corrosion resistance, and application environment.

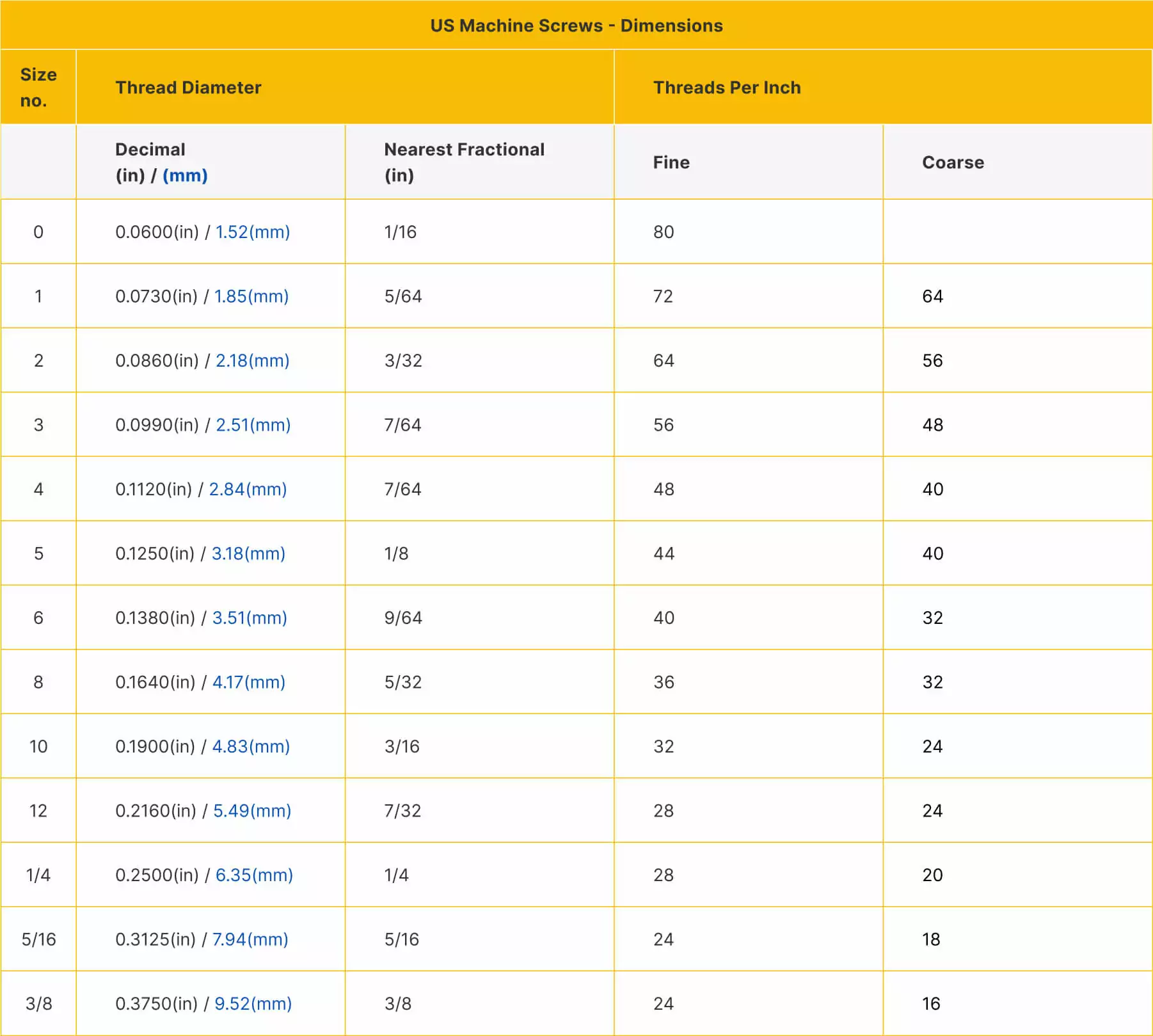

Understanding Machine Screw Sizes and Standards

Machine screws come in a vast array of sizes, but understanding these sizes doesn’t have to be overwhelming. Two key factors define a machine screw’s size:

- Diameter: This refers to the thickness of the screw shank, measured in millimeters (mm) for metric screws and inches for imperial screws. Common metric diameters range from M1.6 (1.6mm) to M36 (36mm), while imperial sizes typically start from #0 (0.060 inches) and go up from there.

- Thread Pitch: This signifies the distance between neighboring threads on the screw shank. A finer thread pitch (more threads per inch/mm) offers a tighter fit and increased resistance to vibration, but may require more torque for tightening. Conversely, a coarser thread pitch allows for faster assembly but might have slightly less holding power.

There are two main international standards for machine screw sizes and threads:

- ISO (International Organization for Standardization): The most widely used standard globally, particularly in the appliance and medical device industries. ISO screw sizes are designated with an “M” followed by the diameter in millimeters (e.g., M5 x 10).

- ANSI (American National Standards Institute): Predominantly used in North America, especially common in the automotive and machinery industries. ANSI screw sizes are denoted by a number representing the diameter followed by a dash and the number of threads per inch (e.g., #10-32).

Here at Cheng Hao, we manufacture and test to both ISO and ANSI standards depending on the customers needs and to ensure compatibility with various components and applications. Additionally, we offer a comprehensive size chart that translates between metric and imperial measurements, simplifying the selection process for you (link to a size chart on your website). Remember, choosing the right size screw is crucial for achieving a secure and functional connection.

If you encounter a situation where a standard size doesn’t perfectly fit your needs, Cheng Hao also possesses the capability to manufacture custom-sized machine screws to meet your specific project requirements.

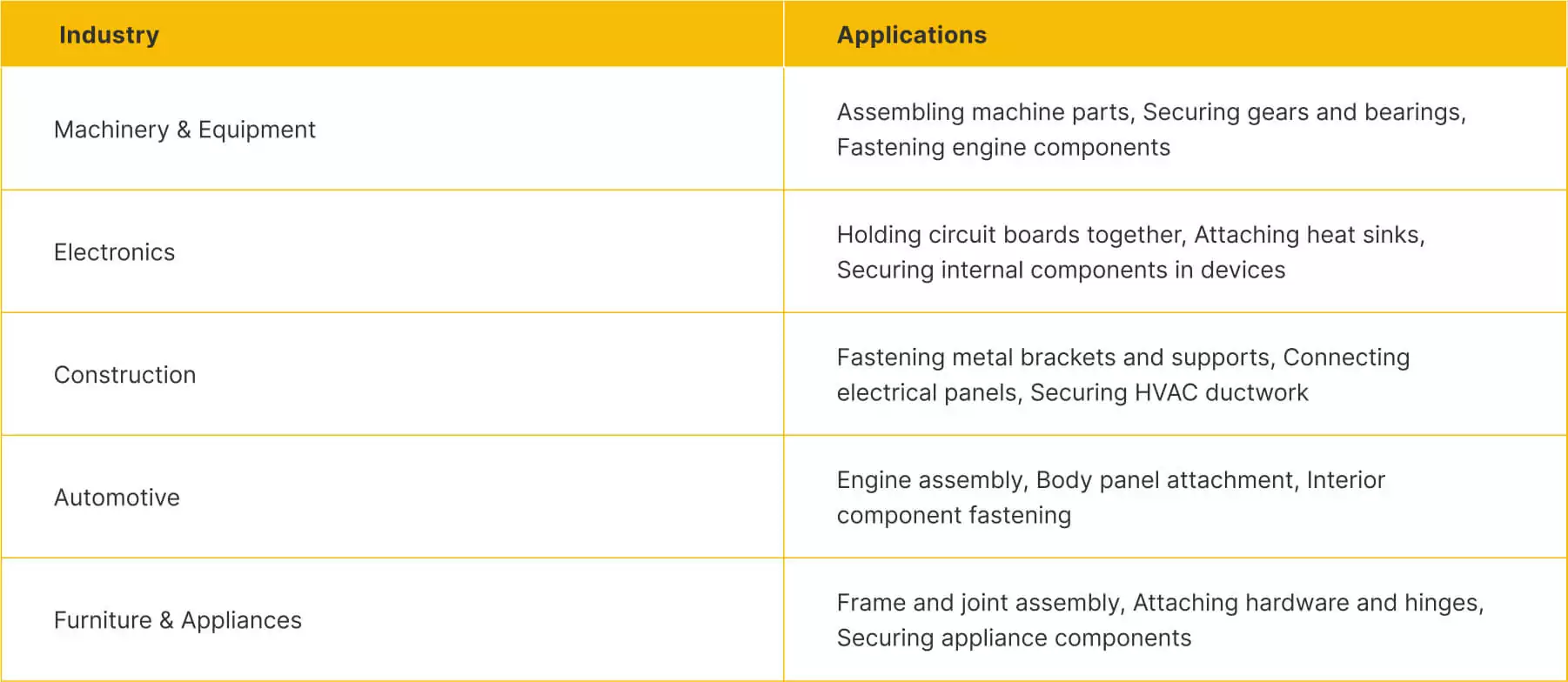

Common Applications of Machine Screws

Machine screws are employed in a wide range of industries and tasks. From automotive engines to construction equipment, they ensure the secure assembly of various metal parts within machinery. In the delicate world of electronics, machine screws play a crucial role in holding together intricate components within devices like circuit boards and computers. Even furniture and appliances rely on machine screws for structural integrity and to fasten various components.

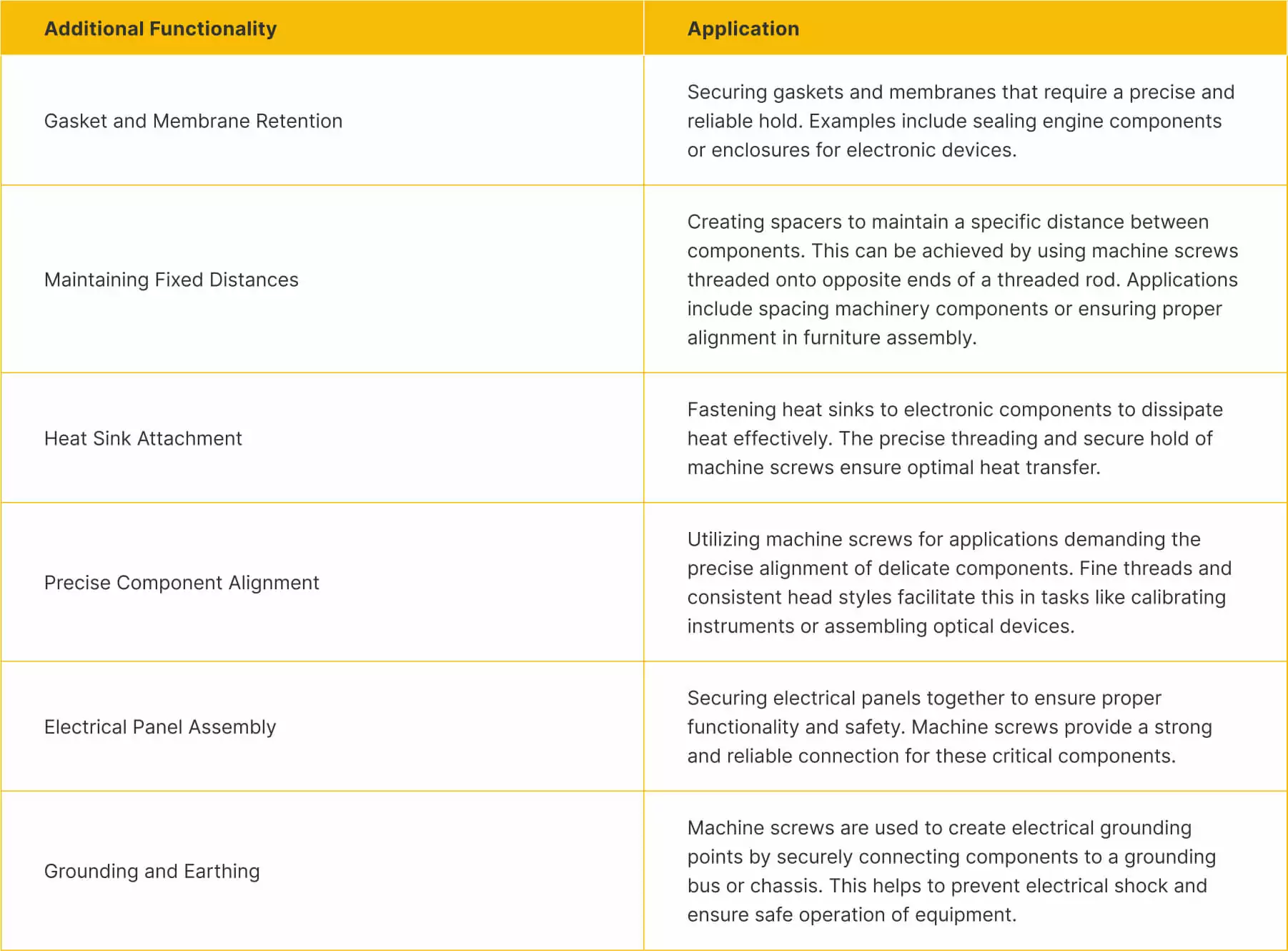

The precision of machine screws means that beyond basic fastening, they offer additional functionalities in many applications:

Cheng Hao Screws Packaging Options

At Cheng Hao Screws we understand that each customer will have their own requirements for packaging based on your market needs, so whether these are in bulk or retail packaging, we can meet your needs.

- Bulk Boxes: For large orders or industrial applications, bulk boxes provide a cost-effective solution. Machine screws are carefully packed to minimize movement and ensure protection during transport.

- Compartment Boxes: These segmented boxes offer a great way to organize and store different sizes or types of machine screws. This promotes easy identification and selection during assembly projects.

- Anti-Static Bags: For electronic components or applications sensitive to static discharge, we offer anti-static bags that safeguard your machine screws from electrostatic damage.

- Custom Packaging: Have specific packaging requirements for your project? Cheng Hao Screws can work with you to develop a customized packaging solution that meets your exact needs.

We prioritize clear labeling on all our packaging options, including screw type, size, quantity, and any relevant certifications. If you have any questions about the packaging options, please let us know and we will do our best to accommodate your needs.

Common Machine Screw Questions Answered

1. What is the difference between a machine screw and a regular screw?

Machine screws are precision-made for a tighter fit. They have full threads for a stronger grip, blunt ends for pre-drilled holes, and finer threads for a more secure hold. Regular screws may have partially threaded shanks, tapered ends, and a wider variety of thread options.

2. How do you size a machine screw?

Machine screws are sized in millimeters (metric system) with an “M” followed by a diameter number (e.g., M6). International standards ensure consistent sizing. For a full list of the common machine screw sizes, please see the full list later in the article.

3. Is a self-tapping screw a machine screw?

No. Machine screws require pre-drilled and tapped holes. Self-tapping screws create their own threads in sheet metal, making them a distinct category.

Cheng Hao – Quality and Certified Excellence

At Cheng Hao, we understand the critical role that machine screws play in ensuring the success of your projects. That’s why we are committed to providing the highest quality fasteners, manufactured according to rigorous international standards. Our screws are ISO 9001:2015 certified, testament to our dedication to quality management systems and consistent production of superior products.

We manufacture a wide variety of machine screws, including Lathe Tool Holder Screws, Standard Machine Screws, Micro Machine Screws, and more. No matter your specific needs, we have the right machine screw to get the job done. Please contact us to find out more about our machine screws for your project.