The Ultimate Guide to Tek Screws for Thick Metal

- NSSC 550 Series Screws

In construction and metalwork, the significance of using the correct fasteners cannot be overstated. Especially when dealing with thick steel, the choice of screws can make or break the integrity and longevity of the structure. Enter Tek screws, a pivotal solution for fastening thick metal sheets with ease and reliability. These screws are designed to tackle heavy-duty tasks where standard screws fall short. In this article, we delve into the mechanics of Tek screws, particularly those designed for thick steel, offering insights into their application, benefits, and selection process.

Table of Contents

Section 1: Understanding Tek Screws

Tek screws, known for their robustness and efficiency, are a class of fasteners that have revolutionized the way we approach securing metal. But what exactly are Tek screws? They are self-drilling screws equipped with a sharp cutting tip that allows them to pierce through metal without the need for a pilot hole. This self-drilling capability is what sets them apart from other screws and makes them particularly useful for thick metal applications.

Originally developed to speed up construction without sacrificing strength, Tek screws have evolved into an indispensable component in various industrial and commercial projects. They come in different shapes and sizes, each tailored for specific materials and thicknesses. Their design is a testament to the advancements in fastening technology, where each element of the screw serves a purpose—from the drilling point that slices through metal to the threads that provide the grip necessary for a firm hold.

Understanding the specific applications and limitations of Tek screws is crucial for anyone working with metal. They are not just screws; they are precision tools that, when used correctly, can enhance the structural integrity of a project. With a range of types and sizes available, selecting the right Tek screw requires a knowledge of the metal’s properties and the demands of the task at hand. In the following sections, we will explore the different types of Tek screws, their applications, and how to select the right one for your project.

Section 2: Self Drilling Screws for Thick Metal

When it comes to fastening thick metal sheets, self drilling screws stand out for their efficiency and reliability. These screws are specifically engineered to drill into metal, carving their own pilot hole as they are driven. The key feature that allows them to do this is the self-drilling tip, which is designed with a precise cutting edge that acts like a drill bit. This tip is typically made of high-grade steel that has been heat-treated to withstand the rigors of drilling through tough materials.

The advantage of using self-drilling screws for thick metal is twofold. First, they save time by eliminating the need to pre-drill holes, which is a labor-intensive and time-consuming process. Second, they ensure accuracy since the screw drills its own hole, there is less likelihood of misalignment, which can occur when separate drills and screws are used.

However, not all self-drilling screws are created equal. The thickness of the metal and the type of steel it is made of will dictate the kind of self-drilling screw needed. For instance, drilling into a 5mm thick stainless steel plate requires a different type of screw than drilling into a 12.5mm thick iron plate. The hardness of the drill point and the length of the flute—the grooved part of the screw that allows for material removal—are critical considerations. A longer flute is necessary to clear out the swarf, or debris, from drilling, which prevents overheating and preserves the integrity of the screw’s tip.

Section 3: Self Tapping Screws vs. Self Drilling Tek Screws

While the terms ‘self-tapping’ and ‘self-drilling’ are often used interchangeably, they refer to two distinct types of screws. Self-tapping screws are designed to tap their own threads into pre-drilled holes in metal. They are useful for thin metals but are not suitable for thick metal without a pilot hole. On the other hand, self-drilling screws, commonly referred to as Tek screws in the United States, do not require a pre-drilled hole because they have a drill bit-like tip that can pierce through metal before the threading begins to take hold.

Self-drilling Tek screws combine the actions of drilling and tapping into one step, which not only streamlines the process but also provides a stronger hold due to the precise fit of the threads they create. The efficiency of self-drilling screws makes them the superior choice for thicker metals, where pre-drilling would be impractical.

When selecting a screw for thick metal, it is important to consider the Tek number, which indicates the length of the self-drilling tip. The higher the number, the thicker the metal it can penetrate without a pilot hole. For example, a Tek 5 screw has a longer drilling tip than a Tek 3 screw and is capable of drilling through thicker metal. Understanding the distinction between self-tapping and self-drilling screws, as well as the Tek classification, is essential for professionals to choose the right screw for their specific application.

Section 4: Tek Screw Sizes and Selection for Thick Metal

Choosing the right size of Tek screw is pivotal for ensuring the strength and durability of the metal joint. Tek screws are available in a variety of diameters and lengths, each designed to accommodate specific thicknesses of metal. The size of a Tek screw is typically denoted by a number, such as #12, which indicates the screw’s diameter, and a Tek number, such as Tek #3 or Tek #5, which specifies the length of the drill point.

For thick metal applications, it is essential to select a screw size that not only matches the thickness of the materials being joined but also the type of metal in use. For example, a #12 screw with a Tek #5 drill tail is designed for penetrating thicker and harder metal plates, like those made of high-strength steel. On the other hand, a Tek #3 point may suffice for softer, albeit thick, metal substrates.

When selecting a Tek screw, professionals must also consider the type of head, thread pattern, and the driving recess that is best suited for the job. The head style, whether flat, pan, or hex, will determine how the screw sits against the material, while the thread pattern will affect how the screw bites into the metal to provide the necessary holding power. The driving recess, such as Phillips, square, or Torx, must match the driver bit to ensure efficient installation without slippage.

In addition to the physical dimensions, the material composition of the screw plays a significant role. High-grade steel screws may be necessary for the most demanding applications, while coated screws offer additional corrosion resistance for outdoor or humid environments. It’s not just about the size; the right combination of size, material, and design ensures the Tek screw will perform as needed for thick metal applications.

Section 5: Advanced Tek Screws: NSSC550 and Corrosion Resistance

Beyond standard Tek screw selections, the market offers advanced options such as the NSSC550, a premium grade of stainless steel screws. These screws are particularly renowned for their superior corrosion resistance and enhanced drilling capabilities. NSSC550 screws are a compelling choice for heavy-duty applications where environmental factors such as moisture, salt, and chemicals are a concern.

The anti-corrosion properties of NSSC550 screws are substantiated by rigorous testing, including salt spray and Kesternich tests, where they exhibit resistance to rust far beyond that of conventional screw materials. These tests simulate long-term exposure to corrosive elements, demonstrating the screw’s ability to withstand harsh conditions without significant degradation.

The exceptional hardness and strength of the NSSC550 screws also allow for drilling into thick metal without the need for pre-drilled holes, making them a suitable choice for projects requiring quick installation and long-term durability. The high surface and core hardness ratings indicate that these screws can maintain their structural integrity even when penetrating the toughest materials.

When it comes to fastening thick metal, professionals often turn to Tek screws for their reliability and strength. However, not all Tek screws are created equal. Advanced materials like Hitachi Metals ASL503 and Nippon Steel YUS550 have set new benchmarks in the industry for self-drilling and self-tapping screws.

Marutex Screws with ASL503

Japan’s MIYAGAWA METAL has crafted a revolutionary one-piece self-drilling, self-tapping screw known as “Marutex.” These screws are manufactured using Hitachi Metal’s ASL503, an improved variant of Asada loose iron stainless steel. Containing 13% Chromium, ASL503 boasts a low hardness after annealing, which aids in its remarkable cold workability.

Upon quenching and tempering, it exhibits superior hardness and tensile strength, reaching over HRC50, allowing it to effortlessly drill into steel plates up to 12mm thick. Its shear strength is nearly double that of traditional carbon steel screws while maintaining corrosion resistance on par with SUS304 stainless steel. Marutex screws represent a perfect amalgamation of high hardness and exceptional corrosion resistance, suitable for a myriad of applications.

Nippon Steel’s YUS550 Stainless Steel Innovation

Nippon Steel’s introduction of YUS550 stainless steel has transformed the capabilities of tek screws for thick metal. This material is an enhancement of Asada loose iron stainless steel, augmented with trace amounts of Nitrogen and Molybdenum. The result is a stainless steel that not only shares the corrosion resistance traits of SUS304 but can also achieve a hardness of approximately 550Hv after heat treatment.

YUS550 is ideal for crafting automatic drilling self-tapping screws, high-strength nails, fork pins, high-strength chains, and other hardware that demand extreme hardness coupled with corrosion resistance. Its standout features include:

A maximum strength of 1800 MPa and hardness up to Hv600.

Corrosion resistance that rivals 304 stainless steel, ensuring longevity even in harsh environments.

Testing and Certification of NSSC550 Screws

NSSC550 screws undergo rigorous testing to ensure their quality and durability:

- Anti-Corrosion: They have been tested in salt spray conditions for 6,000 to 15,000 hours, showcasing an anti-rust effect that is 15 times better than conventional materials.

- Acid Resistance: They exceed 100 cycles in Kesternich testing without signs of rust, indicating high resistance to acidic conditions.

- Hardness: These screws have a surface hardness ranging from 620 to 635 HV and a core hardness of 559 to 563 HV, ensuring they maintain their integrity even under extreme stress.

- Strength: The tensile strength of NSSC550 screws is between 1500 to 1586 N/mm2, making them incredibly robust for industrial use.

- Certification: These screws have earned the EU ETA Certificate, attesting to their compliance with European standards for construction screws.

Common Applications for Tek Screws:

- HVAC Installations: Securing ductwork and attaching components within heating, ventilation, and air conditioning systems.

- Roofing: Fastening metal sheets to wood or metal frames, especially in commercial metal roofing.

- Building Cladding: Attaching metal cladding panels to the structural framework of buildings.

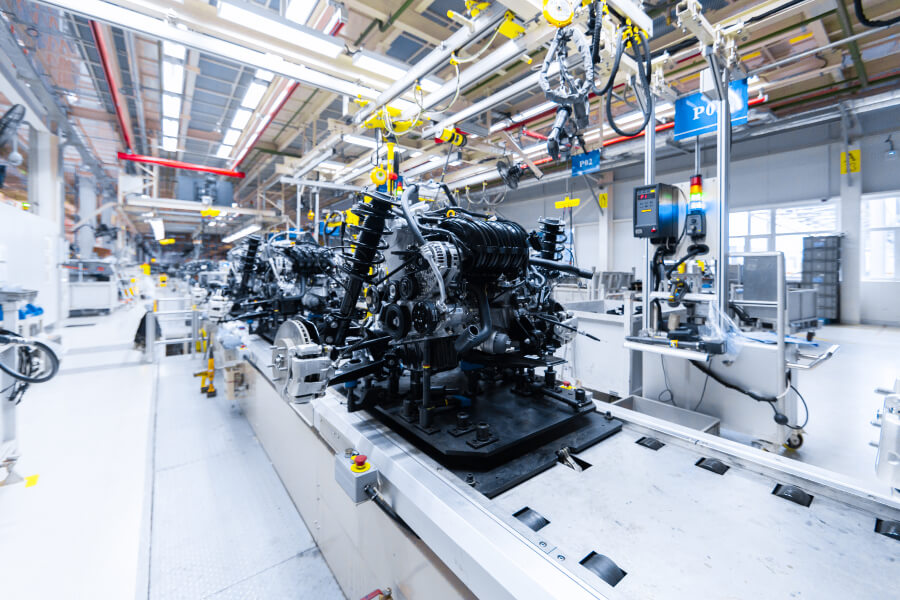

- Automotive Assembly: Joining metal parts in the construction of vehicles and trailers.

- Solar Panel Mounts: Affixing solar panels to metal frames or rooftops.

- Steel Framing: Connecting steel studs and tracks in light-gauge steel construction.

- Railroad Car Manufacturing: Fastening components in the construction of rail cars.

- Shipbuilding: Attaching parts in both the superstructure and hull of ships.

- Metal Furniture Construction: Assembling metal desks, chairs, and storage units.

- Industrial Shelving: Erecting shelving units and storage racks in warehouses and storage facilities.

- Signage and Billboards: Securing large metal signs and billboards to their supports.

- Electrical Enclosures: Fastening components within electrical boxes and cabinets.

- Outdoor Construction: Building decks, pergolas, and other outdoor structures with metal elements.

- Fencing and Railings: Attaching metal fencing panels and railings to posts.

- Agricultural Equipment: Repairing and assembling machinery and structures used in farming.

- Metal Door and Window Frames: Installing frames securely into masonry or metal structures.

- Aerospace Components: Used in the assembly of various non-structural components within aircraft manufacturing.

For those tackling the challenges of thick metal, the right Tek screw can make a significant difference in the quality and efficiency of their work. NSSC550 screws represent a leap forward in screw technology, providing high durability, precision, and the strength required for demanding industrial applications. With the appropriate selection and application of these certified Tek screws, professionals can ensure a secure and lasting bond in their metalwork projects.