Your Trusted Custom Screw Manufacturer: Excellence in Every Turn

As a custom screw manufacturer with more than twenty years of experience, we specialize in precision manufacturing. Our team includes seasoned professionals dedicated to their expertise. We have completed numerous projects, consistently meeting and often surpassing our clients’ expectations in terms of quality and precision. This article will outline our collaborative process, ensuring you find the most suitable solutions for your projects efficiently.

Table of Contents

Custom Screw Manufacturer for your Projects

At our company, we don’t believe in one-size-fits-all. We understand that each project has unique requirements. That’s why we offer a bespoke service, producing custom screws to your exact specifications. Whether you need screws for automotive applications, medical devices, or consumer electronics, we have the expertise and capabilities to deliver.

Getting Started: Information We Need

If you already have clear specifications for your requirements, please provide them directly to us. If you are less certain or need some more guidance on the information that we will need to fulfill your requirements, please have a look at the sections below for an overview or contact us directly if there is anything that you are unsure about and we will work with you to develop and check the specifications to meet your needs.

Specifications

To start the process we will need some specific details about your needs.

- Type of Screw & Application

- Dimensions

- Head Type

- Driver Type

- Thread Type

- Point Type

- Materials

In addition to this information we also offer a wide range of surface treatments that are suitable for different applications:

- Zinc

- Zinc Nickel Alloy

- Yellow Zinc

- 6 Lobe

- Ruspert Silver

- Powder Coating

- Thread Lock

- Nickel

- Black Oxide

- Anodizing

If you have any special requirements for your application such as tamper resistance or other needs, please also note these down so that we can provide the correct solution.

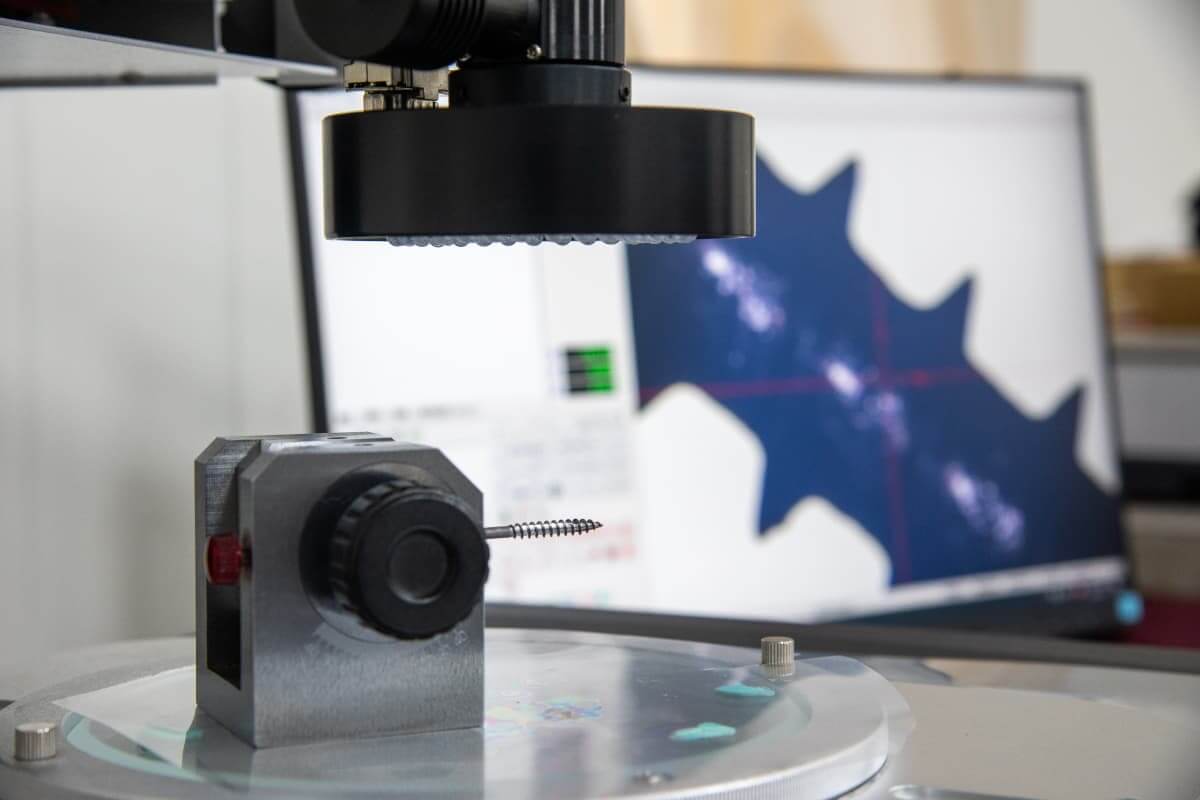

Quality Inspection

Quality inspections and certifications are vital for many countries in order for screws to comply with local building codes and regulations. We can provide EU ETA certification for construction screws for you. We carry out detailed inspections on each batch in our testing lab but if you have specific testing requirements or documentation needs then please let us know and we will do our best to accommodate your needs.

Packaging Options

You will need to consider the packaging options that you need as a part of this process. Whether you are purchasing for B2B or consumer use, we have a range of standard packaging types available and for larger orders we may be able to provide you with custom packaging solutions with your branding as well. Please contact us directly if you have questions about these options.

For even more detailed information please reference our specifications page which covers all of our standard options. If there is anything you cannot find, then please contact us directly and we will provide a solution for your needs.

Custom Designed Fasteners & Parts

Many of our regular customers also have special custom fastener requirements in addition to screws. We have long experience helping customers to design cost effective and innovative fastening solutions and CNC parts that are used in a wide range of industrial and commercial applications.

We are able to offer state of the art CNC parts services that cover, machining, grinding, turning and more. We are also able to offer our customers the full range of surface treatments and quality inspection options for the parts we manufacture. If you would like to find out more about our CNC parts or Stamping parts, please check those pages or contact us for further information.

Going the Extra Mile: Our Additional Services

What sets us apart from other manufacturers is our commitment to providing a complete solution. We offer design consultation to optimize your product for manufacturing, material selection assistance to ensure durability and after-sales support to guarantee your satisfaction. We don’t just manufacture screws; we build long-term relationships with our clients.

If you would like to find out about our custom screw solutions and get a detailed quote for your project, please contact us and we will respond to you without delay.