Definition of Thread Profiles

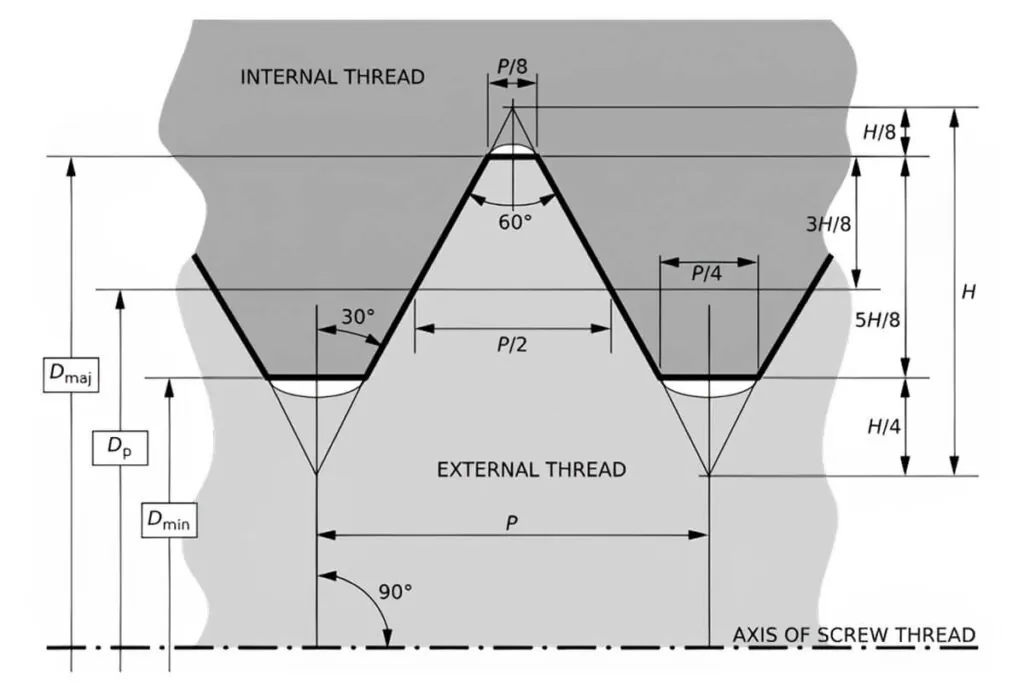

Thread profiles describe the shape and geometry of screw threads. You examine the cross-sectional form of the thread including root, crest, and flank angles. Common profiles include unified, metric, Acme, and buttress. The profile affects strength, sealing, and ease of assembly. Engineers specify profiles to match load, mating part, and material. Buyers check profiles to ensure compatibility with tapped holes and nuts.

Accurate profiles maintain fit and performance in assemblies. In screws and fasteners, correct thread profiles ensure reliable connections, reduce wear, and support expected load conditions.

Choosing the right thread profile helps you meet strength and load requirements. You keep load distribution even across engaged threads, so assemblies hold under stress.

Using a compatible profile prevents cross-threading and fit issues. If you mix incompatible profiles, you risk thread damage and failure.

You save time and cost by standardizing on common profiles. You ensure fasteners work with existing nuts, taps, and equipment, avoiding delays.

Related Terms

Thread pitchThread tolerances

Thread angle

Unified thread form

Metric thread

Buttress thread

FAQ

How does thread profile affect screw strength?

Thread profile influences load distribution across the engaged threads. You get better strength when the profile suits material and application. A mismatched profile can concentrate stress, causing wear or failure under load.

Which standards define common thread profiles?

You refer to ISO metric, Unified (UN), Acme, and buttress standards. Each sets flank angles and dimensions. Check the relevant standard for your region or industry. You match the screw profile to the tapped hole or nut profile defined by these standards to ensure proper fit and function.

How does thread profile influence assembly torque?

Thread profile affects friction and load distribution. You notice that sharper flank angles may change how much torque you need. If the profile matches the mating part, you get consistent torque readings and avoid over- or under-tightening. Always test torque on sample parts to confirm the expected values.